We are one of China’s top manufacturers that offer a one-stop service for 3C items, toys, Plastic and Electronic, Silicone kitchenware, Promotional gifts, Stationery, Car accessories, Bathroom accessories, Bags and Luggage and Other accessories products as well as many other quality consumer products. With our expertise we hope to help you realize your success and economic profits. Therefore, we can establish a friendly long-term “win-win” business relationship together.

IWAIZUMI INTERNATIONAL Idea (Research):

As we all know every successful product began with a sparkling idea based on an informed knowledge base. At IWAIZUMI INTERNATIONAL, our experienced research team offers a professional service to formulate a solid framework for you while keeping your original idea.

Product Formation (Design and Engineering):

Once a solid idea is formed, our innovative design team will prepare a series of product proposals for you to choose from.

Our experienced engineering team will work side by side with you, to ensure that the product is feasible (passes tests and regulations), cost effective, and suitable for mass production. Product prototypes will be presented to give you more insight into the real product.

Tooling:

As soon as the prototype is completed and finalized, our Tooling department will set out to make the mold according to the drawings and customer requirements. Usually the tooling lead time would be from 5 to 30 days (It all depends on the size and complexity of the product).so it takes a lot of patience. When the mold is finished, we will carry out a sample test to make sure the quality of the mold as well as the product. Our tooling department is striving for a zero defect mold according to the strict execution of tooling making procedure. We are confident to deliver zero defect products to our client by our high quality mold and accurate equipment to meet the expectations and trust of our clients.

Sample making:

Our sample making center will deliver the sample according to the strict procedures and customer required Specification and Color. Usually, the sample delivery time would be 4 to 5 days to make sure everything goes well. We are ready to offer our client zero-defect samples and establish a win-win relationship with them.

Mass Production:

As soon as the prototype is completed and finalized, our professional manufacturing team begins to work your project out, including calculating the needed raw material with our purchasing department. Molds will be produced in-house to guarantee accuracy, high quality, efficiency and privacy. Before mass production we will carry out a trial production to make sure everything is right, therefore, ensuring an on-time delivery and error-free production. We are confident that by our top quality manufacturing facilities as well as skillful staff, we are able to providing whatever you want, regardless of size, shape, color, complication, texture and quantity.

Quality Control:

Quality is the lifeline of a company and a quality service is the driving force for its development. We attach great importance to staff training, especially for the quality management training. This will be closer to our vision and mission.

Our quality control department has four major functional modules: Total Quality Management (TQM), Vendor Quality Assurance (VQA), In- Process Quality Control (IPQC), Outgoing Quality Control (OQC).

The four major quality managements play a different role, but they are interrelated.

We start from the product concept to product model form, materials purchase, manufacturing and product packaging and other procedures, we strictly implement quality control processes and the international quality inspection rules, to meet customer needs and expectations and gain their trust.

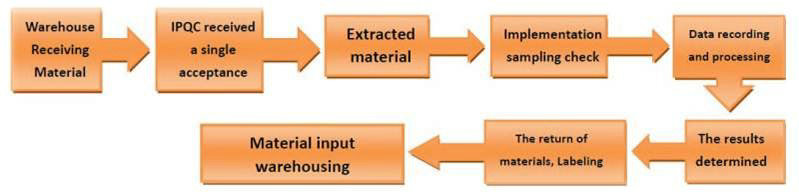

Incoming inspection flowchart:

Packing and Shipping:

Our professional packaging and shipping team is well known for its ability to handle various

Modes of shipping and Communicates regularly with our shipping partners to ensure a safe, reliable, and on-time delivery.